Production Line Machines

This machine was developed to meet the customers requirements for automating one stage of their production line. The machine is capable of accurately drilling, routing and fixing location brackets through a composite panel.

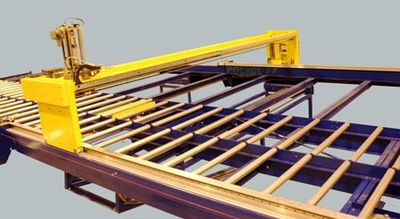

The Dibble XL has been designed at a 10 degree angle to aid loading and uses gravity to "clamp" the panels against the datum edge, where the panels are also automatically driven on rollers. It also has adjustable roller tables for various widths of panel and is equipped with a full range of safety equipment including light curtains, single beam transmitters and pressure sensitive mats.

It is controlled via a HMI (Human Machine Interface) touch screen panel with an inbuilt PLC operating bespoke software control screens. It also has been designed with a bar code reader for accurate selection of the standard .dxf CAD files eliminating any operator error.

This machine significantly improved the throughput of the panels the factory. Quality is also increased, as the accuracy of the machine is within 1mm and the machine marks out the product in a consistent fashion that was not possible with manual techiniques.

The project has been rolled out in phases, starting with a basic positional marking system, followed by a drilling function and latterly a automatic feeding drill and driver head that can accurately fix the brackets into position using a cartridge of pins.

Click here for more Product Details from

Engineering Efficiency...