Stainless Valve Co., Inc.

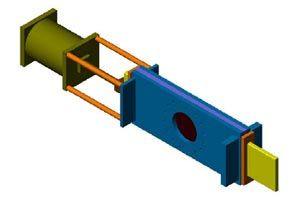

Stargate O-Port AS Valve

When scale is formed on the moving elements of ball valves or gate valves the consequence is either blocking of the valve movement or damage to the valve seats and consequent leaking through the valves. Since its development in 1995 the Stargate O-Port® AS valve has eliminated scaling issues in valve applications.

The special aspect of the AS-Stargate-O-Port® valve is the combination of coatings and seats in order to eliminate the negative aspects of scale formation or sticky flow media. There are a variety of different coatings, which can be applied to the blade. We found the best coating to be used for low temperature applications to be the “High-Build”, which creates a barrier between the blade and the flow media. The “High-Build” has a good adhesion to the blade but the flow media, respectively the scale, does not stick to the “High-Build”. This makes it possible for the seats to wipe the blade clean when the valve is actuated. For high temperature applications mostly a Nickel-based coating is used. Again the desired property is a low coefficient of friction between the coating and the flow media.

The Stargate O-Port® AS valve has been used in a variety of applications including mining, food processing, and liquor heaters, lime storage, and fly ash bins in the pulp and paper industry with great success. One application in a hydrometallurgy autoclave for a gold mine 12” knife gate valves were used that had to be replaced every two weeks. The customer has installed Stargate O-Port® AS valves that have now been in service for 6 years without refurbishment. The Stargate O-Port® AS valve has exhibited similar results in other applications involving sticky or scaling materials.

Click here for more Product Details from

Stainless Valve Co., Inc....