Metallurgical Technologies, Inc.

Case Study: Failure Analysis of Failed Inconel Condenser Tube

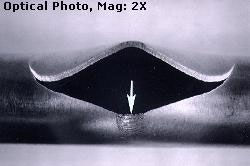

A low magnification view of a rupture in an Inconel 600 condenser tube. A patch of crevice corrosion is found in the center of the rupture site. Corrosion is at a baffle support location.

A cross-section through the tube at the crevice corrosion patch reveals the depth and extent of the degraded area.

Higher magnification of the cross-section details the intergranular nature of the corrosive attack. The grain boundaries are dissolved leaving the matrix intact. The defect is difficult to detect using standard inspection techniques.

SEM (Scanning Electron Microscope) analysis of the corrosion area on the tube OD surface reveals the presence of intergranular corrosion attack. Note the presence of a crystalline structure, indicative of intergranular fracture.

EDS (Energy Dispersive Spectrometry) analysis of the corrosion area indicated the presence of caustic material that led to this metal product failure.

Metallurgical failure analysis of a component can prevent recurring failures, help with preventative detection, or suggest remedies. If you have a metal product failure that you would like investigated, just take a moment to fill in our contact form and we'll gladly provide you with an estimate.

Click here for more Product Details from

Metallurgical Technologies, Inc....