Contact Details:

Aquila

Taste International Ltd, 2818 Tower A

No.325 Tian Yao Qiao Road

Shanghai

200030

China

Tel: +86 21336 32028

Fax: +86 21336 32307

Send Enquiry | Company Information

The importance of getting the right yarn for cut resistant gloves by Kwan Lo, M.D. Aquila®

Company News Thursday, May 28, 2015: Aquila

The development of lightweight but highly effective, comfortable and hardwearing cut resistant gloves for all types of industrial environment is one of the little acknowledged success stories in health and safety technology. This has generally involved development and use of tougher materials, sometimes blended with steel threads and using traditional glove weaving technologies. In recent years however we have seen rapid progress in the production of spiral wound yarns which further facilitate an advanced blending of materials and physical characteristics in the final garment. This has become especially applicable to glovewear, with major benefits in length of protective capability, wearability and comfort, producing a service life through extended wash cycles even to 14 times. This has led to an improvement in personal protection together with a significant reduction in lifetime cost as well as the many work related benefits such as improved comfort and dexterity.

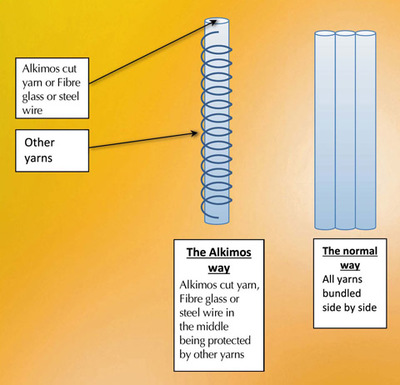

The unique Alkimos® yarn technology used in Aquila® cut resistant gloves employs a spiral fibre winding of ultra high density polyethylene as a protective and structural support outer layer to the core fibre. The yarn is consequently extremely tough with the core fibre protected from mechanical damage such as breakage or fraying in the wash process. This is why gloves manufactured with Alkimos® yarn are able to maintain their extremely high performance for an exceptional number of wash cycles.

Repeated washing saves a considerable replacement cost, and with up to 14 washes without degradation of cut test performance Alkimos® yarn means gloves can frequently exhibit double the working life compared with other mainstream products.

This longevity of protective capability greatly enhances the safety and comfort of individual workers since the same Alkimos® technology minimises mechanical degradation and enhances wearability in the workplace. The spiral wrapping supports core fibres in the flexing of day to day wear so ensuring a soft comfortable fit without the itchiness associated with release of glass micro-fibres.

The Alkimos® spiral wrap technology facilitates the use of multiple fibre blends with steel, glass fibre, nylon or other material as the core wrapped in the ultra-high density polyethylene thread. Thus it is possible to choose the cut protection level appropriate to the environment and risk profile of the operation, with confidence that this protection will continue to perform at its optimal specification for a greatly extended period.

This spiral weave provides a tough support sleeve that protects and cushions the main core fibres against the mechanical damage of cuts, impact, bending etc. and so maintains the integrity of the yarn and of the weave so that the completed glove can continue to perform at its optimum for the longest possible duration.

A major benefit of this cushioning effect is the greatly reduced presence of fibre particles so increasing comfort when new and ensuring it is maintained for the lifespan of the glove.

With each core fibre firmly cushioned in its own protective sleeve it becomes possible to pay closer attention to design and detail finish of the glove itself with confidence that the glove will retain its shape and structure very closely to the production specification even after extended periods of wear and washing.

Ultimately a better cut yarn means a better glove and better cut resistance.

Further information regarding Aquila® products may be found at: www.aquilaglove.com or follow them on twitter: www.twitter.com/@aquilaglove.