Contact Details:

Huntingdon Fusion Techniques Limited

Stukeley Meadow

Gwscwm Road

Burry Port

Carmarthenshire

SA16 0BT

United Kingdom

Tel: +44 1544 836836

Fax: +44 1544 836837

Send Enquiry | Company Information

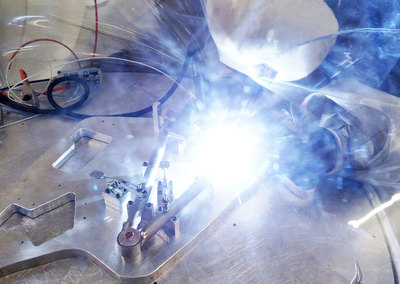

Flexible Welding Enclosures® for Zero Colour Titanium Welds

Product News Monday, August 8, 2016: Huntingdon Fusion Techniques Limited

When welding titanium, zirconium and some stainless steel joints it is important that the welding zone is purged of oxygen to a level as low as 10 parts per million (ppm).

Flexible Welding Enclosures® are available from Huntingdon Fusion Techniques HFT® for a fraction of the cost of a rigid welding chamber. Flexible Welding Enclosures® provide a solution where a rigid chamber may not be economically viable or where space may be at a premium.

Ron Sewell, Chairman for HFT® said: “In his workshop in Santa Rosa, California, retired CEO Bob Lee is recreating a famous Can-Am racecar, the Ti22 that was destroyed in 1973. This car was the first Monocoque road racecar to make extensive use of titanium. With over 40 years of experience of welding titanium, Huntingdon Fusion Techniques HFT® have become very involved in this project, providing equipment and technical assistance where required.

The Ti22 titanium suspension, bulkheads and subframe will be welded inside HFT’s 60” Flexible Welding Enclosure® providing a very fast purging time down to a few parts per million of oxygen, ensuring oxide free, zero colour titanium welds are achieved.”

Size for size, HFT®’s range of Flexible Welding Enclosures® can cost less than one tenth of a metal glove box and less than one hundredth of a vacuum system. These enclosures provide fast purging times down to a few ppm of oxygen and are ideal for small production quantities of parts that need total gas coverage.

It is not only racecar manufacturers that have taken advantage of the low cost, easy to use Flexible Welding Enclosure®, industries such as aerospace, automotive, biochemical, medical, food, beverage, semiconductor and nuclear sectors have also been producing zero colour welds inside these welding bubbles. More recently, companies experimenting with wire plus arc additive manufacturing (WAAM) have also invested in these enclosures.

The standard enclosures are manufactured with two sets of glove ports as standard and the upper half of the enclosure, above the arm entries is optically clear, providing excellent welding vision. A transfer sleeve makes it possible to pass small parts in or out of the enclosure without affecting the purge quality.

As in the case of the robot manufacturing cells and for laser and arc additive manufacturing applications, special enclosures can be designed and manufactured to suit.

Operator comfort and ease of use with Argweld® Flexible Welding Enclosures® versus the disagreeable conditions with a rigid plastic or metal chambers make the HFT® versions a big hit with welding personnel.

Flexible Welding Enclosure YouTube Video is available at:

https://youtu.be/ZlYO0PYTTro