Contact Details:

BEI Kimco

1499 Poinsettia Ave Suite 160

Vista

CA

92081

United States of America

Tel: +1 760 597-7042

Alt. Tel: +1 800 572-7560

Fax: +1 760 597-6320

Send Enquiry | Company Information

Voice Coil Actuator or Solenoid:Choose the Right Component for the Application

Product News Monday, July 2, 2012: BEI Kimco

Voice Coil Actuator or Solenoid:Choose the Right Component for the Application

By Jim McNamara, BEI Kimco Magnetics, Senior Application Engineer

When it comes to linear motion, engineers often come down to two choices: Voice Coil Actuators (VCAs) and Solenoids. Both of them are simple electromechanical devices that can accomplish the task. But there are definite differences between the two and it is important for the designer to select the component most suited for the function required. By comparing the design and capabilities of the two components, it becomes easy to determine which is the most appropriate to use in a given application.

Solenoids

Solenoids normally consist of a coil (no magnet) attached to a soft magnetic housing, an iron (or steel) core, and often a spring. Solenoids are on-off devices that can be controlled by simple switches. When the current flows through the coil, the iron core is attracted by the electro-magnetic field created by the coil. When the coil is de-energized, the spring pushes the iron core back to its original position . In some applications solenoids without springs are used to move a common iron core back and forth. In all cases, solenoids can be designed to achieve a certain speed and a certain amount of force. But once set, it cannot be altered to make adjustments to the movement required, i.e., it cannot provide any controlled changes in speed, force or position. Solenoids meet the simple linear movement requirements at a low cost in a simple on-off control mechanism.

Suitable solenoid application examples include car starters, ticket machines and many others where a machine needs to be turned on or off. If the application requires more than simple on-off control with precise positioning, then VCAs must be considered.

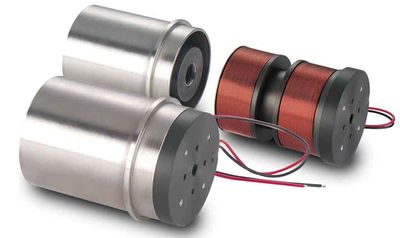

Voice Coil Actuators

VCAs come in many shapes and sizes. There are two types: VCAs with a moving coil and VCAs with a moving magnet. The first type consists of the usually stationary field (magnet) assembly and the moving coil assembly. In contrast, moving magnet VCAs have the coil attached to a stationary soft magnetic housing, which also serves as a conductor of the magnetic flux. The field assembly typically consists of an axially magnetized permanent cylindrical magnet and two soft magnetic pole pieces attached to both ends of the magnet.

Applying a voltage across the terminals causes the VCAs’ moving part (magnet or coil) to travel in a given direction. Reversing the polarity of the applied voltage will change the direction of the moving part (magnet or coil). The generated force is proportional to the flux crossing the coil and the current that flows through this coil. Voice coil actuators are designed for a given stroke. Typically, for a given current, the force created by a VCA at mid stroke is approximately 15% higher than the force created at both ends of the stroke.

Voice coil actuators shine in applications where more precise control is needed, primarily because they can be supplied with position feed-back devices. Second, with low moving mass, VCAs are ideal for many oscillatory applications such as stabilization platforms and shaker tables. Additionally, because moving magnet voice coil actuators consist of a stationary coil and a moving permanent magnet assembly (versus a coil assembly and a piece of steel in a solenoid), VCAs can typically create more force than solenoids for a given size, stroke and input power.

Voice coil actuators with moving coils are ideal for many limited angle rotary applications that require high acceleration. The fast acceleration capability is achieved by minimizing the moving mass - in this case, the moving coil. Since it is separate from the magnet, it can be designed to be more lightweight than the heavy permanent magnet field assembly, allowing extremely fast speeds. Rotary voice coil actuators are commonly found in gimbal applications where fast but controlled moves are required for azimuth and elevation axes. Gimbal application examples include antennas, ‘pan and tilt’ security cameras, target acquisition, laser pointing, scanning and stabilization.

The physical characteristics of a VCA also make it a preferred choice in medical, aerospace and military applications in which size and weight are as important as its functionality. Many medical equipment applications are required to have high mobility, and every component is required to meet a specified dimension. A VCA can weigh as little as half a pound, making it a perfect solution for such a requirement.

There are definite difference between Voice Coil Actuators and Solenoid, and the selection will be based on the application requirement. Voice coil actuators are selected for their technologies and performance. They are high power density devices, so in applications with a short stroke or excursion angle, a voice coil actuator can do the job where other technologies such as motors or gear motors, will be bigger and heavier. Although Solenoids are suitable for on-off linear movement and intermittent duty, VCAs are the obvious choice to control force, speed, travel, and acceleration/deceleration for continuous performance and accurate positioning.

VCA’s provide high force and acceleration capabilities along with high speed linear position control

For further information contact BEI Kimco Magnetics, 1499 Poinsettia Ave., Suite 160, Vista, CA 92081, USA, Tel: (760) 597-7042; Toll-free: (800) 572-7560; Fax: (760) 597-6320; email: sales@beikimco.com; www.beikimco.com.

About BEI Kimco Magnetics:

BEI Kimco Magnetics is a brand of Custom Sensors & Technologies (CST). BEI Kimco Magnetics was founded in 1974 and is a leading manufacturer of high speed, fractional horsepower brushless bldc motors, voice coil actuators, smart voice coil actuators and bldc motor controllers for the Transportation, Industrial, and Aerospace & Defense markets. These products are used across a wide range of applications including medical and scientific, factory and office automation, optics, semiconductor/electronics, military, aviation, space systems, and security. Kimco merges leading-edge capabilities and cost-effective manufacturing know-how with highly customized applications expertise. www.beikimco.com

About Custom Sensors & Technologies:

Custom Sensors & Technologies (CST) is a specialist in sensing, control and motion products. Through its brands, BEI Kimco, BEI Sensors, BEI PSSC, Crouzet, Crydom, Kavlico, Newall and Systron Donner Inertial, CST offers customizable, reliable and efficient components for mission-critical systems in Aerospace & Defense, Transportation, Energy & Infrastructures, Commercial & Industrial OEMs, Medical, Food and Beverage and Building Equipment markets.

Focused on premium value offers and committed to excellence, CST, with 4,700 employees worldwide and sales of $660M US in 2011, is the dependable and adaptable partner for the most demanding customers. www.cstsensors.com