Contact Details:

Wheelabrator

1606 Executive Drive

LaGrange

GA

30240

United States of America

Tel: +1 706 884-6884

Fax: +1 706 884-0568

Send Enquiry | Company Information

Airblast Etching System

Product News Monday, June 4, 2007: Wheelabrator

Wheelabrator designs Airblast Etching System for pressure plate manufacturing

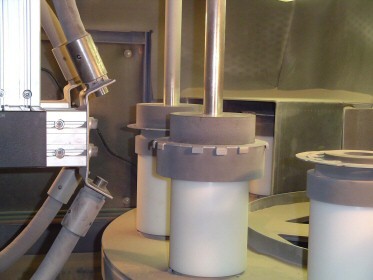

Continuing its leadership in automotive and aerospace surface finishing solutions, Wheelabrator designed and manufactured an automated airblast etching system for pressure plate manufacturing. The process required a suitable ‘etched’ finish to be imparted on one or both sides prior to introducing the pressure plate to a bonding process.

Consistency and repeatability of finish were critical in this high-production process. Utilizing its rich background in critical aerospace and automotive applications, this Wheelabrator® system incorporated:

- Precision nozzle manipulator to horizontally oscillate the blast nozzles along the width of the area being etched.

- Vibratory classifier to classify 100 percent of the blast media, thereby ensuring consistent media size every cycle.

- Closed-loop feedback circuit for air pressure – another critical variable in achieving consistent etched finishes.

- Easy-to-use operator interface with capability to create, store and retrieve part techniques/recipes.

This application also required some pressure plates to be etched on one side and others on both sides. Wheelabrator controls made it convenient to select part recipes that would enable selectively turning nozzles on and off, as required by that particular part type.

A unique, two-piece masking arrangement presented a flat seat to mask the machined surface of the pressure plates. The second part of this mask was powered and located in the blast zone. This ‘dynamic’ mask lowered itself over the part thereby not only masking the top portion of the pressure plate from overspray, but also providing a ‘hold-down’ when processing thin parts.