Contact Details:

Wheelabrator

1606 Executive Drive

LaGrange

GA

30240

United States of America

Tel: +1 706 884-6884

Fax: +1 706 884-0568

Send Enquiry | Company Information

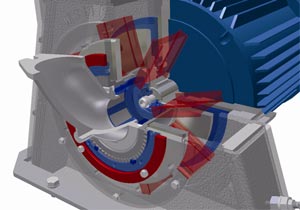

EZEFIT blast wheels achieve unprecedented reductions in cleaning cycle times

Product News Tuesday, June 30, 2009: Wheelabrator

Saving money on overall wheel blast operating costs and maintenance expenses is more important now, in a down economy, than ever before. This new Wheelabrator® wheel (introduced in 2003) has a proven track record with over 2,000 units successfully installed on a variety of blast equipment. Serving a wide range of applications and industries, the EZEFIT® wheel installations have assisted customers in achieving unprecedented reductions in cycle time along with a significant increase in the wear life of blades. Customers have reported reductions in cycle times ranging from 20 to 50 percent and increased productivity within their facilities.

The EZEFIT mounting hardware allows for upgrades on most wheel blast machines (Wheelabrator and non-Wheelabrator) that include Tumble Blast, Spinner Hanger, Monorail, Table, and Railcar Shot Blast systems.

Now available with a unit bearing for belt-driven applications, the EZEFIT wheel contains all of the features and benefits of the direct drive wheel. Additional selling features include (1) elimination of a mounting base plate, (2) a 50 percent reduction in both vibration and wheel assembly time, and (3) fail-safe wheel component alignment.

Wheelabrator Group is a global provider of surface preparation and finishing solutions. Committed to offering the broadest array of technologies, products, replacement parts, services and technical know-how, the Wheelabrator Group works closely with customers to deliver the best solutions for their specific requirements. The company''s strategically located and electronically linked offices allow Wheelabrator Group to provide unrivalled customer service and support worldwide.