Contact Details:

RITZ Pumps South Africa (Pty) Ltd

5a Patrick road

Jet Park

Boksburg

Gauteng

1459

South Africa

Tel: +27 87 8057267

Alt. Tel: +27 11 3975616

Fax: +27 11 3975620

Send Enquiry | Company Information

MC-T - Modular Cooling Technology

Product News Monday, September 14, 2009: RITZ Pumps South Africa (Pty) Ltd

Until now the answer for water-cooled motors was “derating”. With this method, a high-output motor is deployed for a much lower power requirement. However, “derating” was, and still is, a makeshift solution. It is clear why this is not a sustainable, long-term solution:

- High investment costs

- Increased energy costs

- Greater well diameter

- High starting currents

- Limited motor range

The second option – particularly where the media temperature is above 50 °C – is oil cooling. In the event of a defect, this technology can have devastating ecological consequences. Water and oil cooling. Two established technologies, both with advantages and disadvantages that often cancel each other out.

RITZ is setting a new benchmark with MC-T – Modular Cooling Technology. And drawing a line under all heated debates.

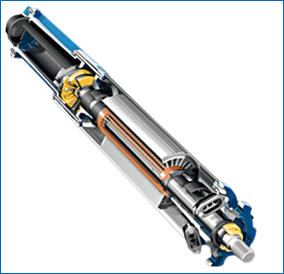

Like many genuine innovations, the principle behind MC-T – Modular Cooling Technology is amazingly simple: Motion!

On the lower shaft end of the rotor there is a suction and pressure-optimised pump impeller. One of its two main tasks is to cool and lubricate the nearby axial bearing. It also ensures a constant flow of cooling liquid in the right direction. This moves upwards through the inside of the motor. Here nothing is left to chance. Cooling channels developed in-house by us define the precise route via all thermal sources to evacuate heat effectively. When it arrives at the top, the heated liquid is transmitted to the outer wall of the motor. There the heat escapes through the surface to the medium being pumped. Now the whole procedure starts again.

The cooling performance can be dimensioned precisely through the use of additional heat-exchanger modules.

MC-T – Modular Cooling Technology is based on four basic elements that together form an unbeatable team.

- The integrated pump impeller ensures a constant flow of cooling liquid in the right direction, thereby preventing the formation of heat pockets which arise when cooling liquid does not move. At the same time the impeller systematically cools and lubricates the axial bearing.

- Optimised cooling circulation featuring specially designed cooling channels ensures that heat is absorbed where it is generated. The system handles evacuation and transports heat effectively to the medium being pumped outside.

- The modular heat exchanger – modern add-on technology – increases the internal volume of coolant and thereby thermal capacity. It also increases the surface area available for transporting heat to the medium being pumped.

- The heat-resistant winding made of various high-quality materials makes it possible to increase technical thermal limits and consequently allows the system to be used at very high temperatures.

An intelligent, compact cooling system, high efficiency even in the partial load range, low wear and tear and zero maintenance. This does wonders for cost-efficiency!

Fact: Operators around the globe already deploy our motor technology. Service life compared to motors with conventional cooling systems was, and is, significantly longer in most cases. Furthermore, MC-T – Modular Cooling Technology works with drinking water – contamination of the water being pumped is therefore excluded.

Key benefits – an overview:

- Media temperatures up to 75 °C

- Drinking water as the cooling fluid

- Zero maintenance

- Maximum operational reliability

- Minimum operating costs